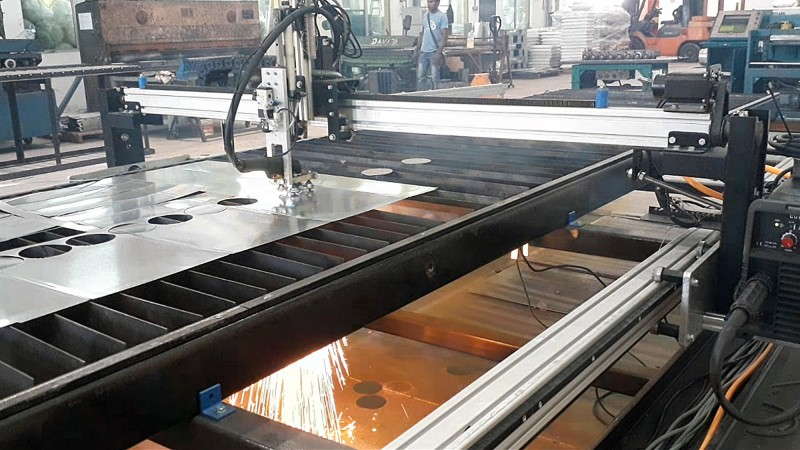

DUCTSYS 1.3m x 4m CNC DUCT CUTTING MACHINE

Home Products Plasma CNC Cutting Machines DUCTSYS 1.3m x 4m CNC DUCT CUTTING MACHINE

Click on image for a larger view!

RM 78000

WATCH THIS MACHINE IN ACTION HERE:

CNC PLASMA CUTTING:

This DUCTSYS CNC is equipped is equipped wit a CNC-enabled plasma cutter that can cut from 0.5mm to 5mm GI (galvanized iron) plate, mild steel, stainless steel and aluminum. Up to 1300mm of cutting width and 4000mm in cutting length, this machine is perfect for cutting ductwork after exiting from the duct beading machine.

PNEUMATIC PLASMA TORCH LIFTER SYSTEM:

As duct cutting machines are required to cut fast, very little time can be wasted on CNC motion. We have specially design a plasma torch lifter system that uses pneumatic air cylinders for instant torch lifting.

COMES WITH CNC COMPUTER SYSTEM:

This DUCTSYS CNC is integrated with a CNC computer system containing all the necessary software for CNC cutting, as well as CNC controller electronics needed for precise CNC motion.

INSTALLATION AND TRAINING INCLUDED:

Upon successful purchase of our DUCTSYS CNC, once the machine has been unloaded to your desired work space with all the necessary power and gas requirements fulfilled, this is what we will do:

- We will install the machine.

- We will provide training.

- By the end of the training you will be able to operate the CNC cutting machine. After a week of continued practice you will be a CNC cutting expert in no time.

AFTER SALES AND SUPPORT:

Sometimes there are problems with the CNC software settings, or maybe you may have forget the steps, or there are some problem with electrical or mechanical. No worries, call our after sales support number and we will attend to you as soon as possible. The good news is up to 95% of the problems can be solved via a phone call.

Our after sales support channels:

- Via Internet Remote Computer Access

- Via Phone Calls and SMS

- Via WhatsApp

- Via On-Site

MADE IN MALAYSIA:

DUCTSYS CNC is proudly designed, manufactured and assembled in Selangor, Malaysia by Mach Robotics, a company that focuses on manufacturing of custom CNC cutting machines as well as CNC repair services. You will be purchasing a locally made CNC cutting machine with local after sales support.

FREQUENTLY ASKED QUESTIONS:

1.WHAT AIR SHOULD I USE FOR PLASMA CUTTING? Plasma cutting requires clean, dry, oil-free compressed air with a minimum pressure of 6 bar, after exiting air filtration and air pressure regulation. Bad air quality such as full of water, or oil will reduce the lifetime of the consumables very much faster. If you want a good cutting edge with minimal cutting burn marks, you can use nitrogen gas.

3. WHY CAN YOU USE NITROGEN GAS OR COMPRESSED AIR FOR PLASMA CUTTING? Essentially, compressed air is our environment air, which already contains 70% to 80% of nitrogen. The remaining percentage is other gases such as oxygen, carbon dioxide, and more. Of course, 100% nitrogen is better.

4. IS THE CNC HARD TO USE? Most of our customers use foreign labor to operate our cutting machines, while they use local labor for cutting file preparation. We also provide training to foreign labors from Bangladesh, Indonesia, Myammar, Burma, etc. Just ensure that they know some form of English/Malay, and knows how to use computer/smartphone! It's a very straight-forward and simplified procedure. We also provide operation manuals just in case your operator does not remember how to use.

5. WHY DO I NEED TO INSTALL GROUNDING FOR PLASMA CUTTING MACHINE? Plasma is actually ionized gas, and is also known as the fourth state of matter. In simple explanation, plasma cutters generate of high frequencies and spreads through the air through gas ionization. To prevent these high frequencies from affecting the CNC controls, computers and nearby devices, it is important to ground the machine body to the earth (workshop floor) using a 10' copper rod installed on the workshop floor. If you relocate the cutting machine, ensure to install the copper rod for grounding. A lot of our customers did not want to install the ground, as a result their controls and computers are frequently damaged. The grounding also serves as protection from thunder and lightning surges.

PRICING: This price for 1.3m x 4m DUCTSYS CNC Cutting Machine is RM78,000.00. For other sizes please contact us.

TECHNICAL SPECIFICATIONS:

- Machine Dimension: Approx. W2000mm x 5000mm x H1300mm

- Cutting Area: W1300mm x L4000mm (4' x 4')

- Plasma Torch Travel: Pneumatic Air Cylinder

- Plasma Cutting Thickness Range: 0.5mm to 5mm (you can request for other cutting thickness, and we will re-quote the price)

- Positional Accuracy: ±0.2mm

- Supported Graphical Files: DXF from AUTOCAD, SOLIDWORKS, CORELDRAW, ILLUSTRATOR

COMES WITH (We supply the following)

- AIRDUCTCUT CNC Cutting Machine

- AIRDUCTCUT CNC Computer System (Integrated into CNC Cutting Machine)

- CNC Plasma Torch Module, installed with Cutting Nozzle

- Installation and Training (Yes, the training is very easy and straight forward)

- After Sales Support

- 1 Year Manufacturer Limited Warranty

- Operator Manual

CUSTOMER PREPARATION REQUIREMENTS (These are the things you need to prepare)

- POWER SUPPLY: 3 Phase 415VAC, Min. 20A

- PLASMA GASES: Clean, dry, oil-free air or nitrogen, minimum 6 bar / 90 psi

- WORKSPACE: Minimum 2 feet more than the machine dimension, of course the larger the better.

- MACHINE OPERATOR: Any person with basic computer/smartphone understanding and English/Malay language, is sufficient for operating our CNC machine.

- (REQUIRED, FOR PLASMA) GROUNDING: 10 feet copper rod grounded to earth, after grounding measure ground resistance to machine body is less than 5 ohms.

Note: We reserve the right to change the details of the product without prior notice. Contact us for an accurate pricing.